Application Of Titanium Alloy in Pressure-Resistant Housing Structure of Submersible

Application Of Titanium Alloy in Pressure-Resistant Housing Structure of Submersible

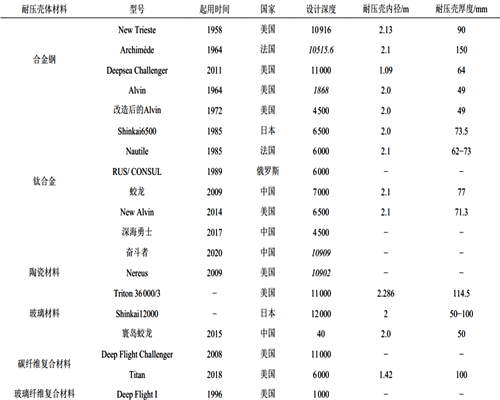

The submersible mainly includes three parts: pressure-resistant structure, attachment structure, and internal frame platform structure. Among them, the pressure-resistant structure resists seawater pressure, provides a stable operating environment for internal instruments and equipment, and provides reliable working and living space for personnel. It is the core component of the submersible.

Alloy steel has high strength and high density at the same time, resulting in the pressure-resistant shell structure made of alloy steel is usually larger in thickness and weight, especially in the case of large submersibles, limited by the weight of the structure and the thickness of the steel plate, the payloads and space that such submersibles can provide are insufficient, which is not conducive to the layout of equipment and the activities of personnel.

The emergence of titanium alloy has solved this problem to a certain extent. Although the strength of titanium alloy is slightly weaker than that of alloy steel, its density is only about 1/2 of that of alloy steel, which has a higher specific strength. At the same time, titanium alloy has excellent resistance to the marine environment and can well meet the needs of underwater equipment. It is currently the most popular metal material in underwater equipment. Almost all the pressure-resistant shell structures of submersibles in service are made of titanium alloy materials. The pressure-resistant shell structures of submersibles such as the Nautile of France, the Shinkai6500 of Japan, and the “Jiaolong”, “Deep Sea Warrior”, and “Striver” developed in China are all made of titanium alloy.

The U.S. Alvin was built in 1964. It originally used alloy steel as the material for the circular pressure-resistant shell structure. The maximum diving depth was 1868m. In 1972, the pressure-resistant shell material was replaced with titanium to increase the working depth to 4500 m. In another modification in 2012, the pressure-resistant shell structure was remanufactured with titanium alloy material, while the diameter of the shell was increased. Compared with the previous modification, the payload was increased and the design depth was further increased to 6000 M.

Shinkai No. 6500 was completed in 1989, with a length ×width×height of 9.7m×2.8m×4.1m, of which the inner diameter of the pressure-resistant ball shell is 2.0m, and it is made of 73.5mm thick titanium alloy. The design depth of Shinkai 6500 is 6500m, and the actual maximum dive is 6527m, which set the diving record of a manned submersible at that time.