Research Progress On Titanium Alloys For Orthopedics

Research Progress On Titanium Alloys For Orthopedics

Development of Titanium Alloy For Orthopedics

There are three main types of metal materials used in orthopedics: Titanium and Titanium Alloys, medical stainless steel, and cobalt-chromium alloys. Among them, the Ni, Cr, Co and other elements commonly contained in stainless steel and cobalt-chromium alloys have toxic side effects on the human body. The elastic modulus of stainless steel is about 210GPa, cobalt-based alloys are about 240GPa, and human bones are about 20-30GPa, which inevitably produces stress shielding. The elastic modulus of some titanium alloys is 20-100GPa, which is similar to that of bones.

At present, the new types of Β-titanium alloys that have been successfully developed and can be applied to orthopedics are: Ti-13Nb-13Zr(United States), Ti-12Mo-6Zr-2Fe (United States, TMZFTM, metastable β-titanium alloy, fine α phase precipitated during aging, put into clinical use, Shrek made femoral shank), Ti-13mo-7Zr-3Fe (United States, TMZF, manufacturing artificial hip joints), Ti-12mo-5Zr-5Sn, Ti-15Mo (United States), Ti-15Mo (United States), Ti- 16Nb-10Hf, Ti-15Mo-2.8Nb-0.2Si, Ti-15Mo-5Zr-3Al (Japan), Ti-30Ta (Germany), Ti-45Nb (United States), Ti-35Zr-10Nb (United States), Ti-35Nb-7zr-5Ta (United States, Ti-Osteum, manufacturing artificial hip joints), Ti-29Ni-13Ta-4.6Zr (TNTZ, Japan), Ti-8Fe-8Ta, Ti-8Fe-8Ta-4Zr, Ti-2.5Al-2.5Mo-2.5Zr (TAMZ, China), Ti-24nb-4Zr-7.6Sn (Ti2448, Institute of Metals, Chinese Academy of Sciences, developed elastic bone plates, spine dynamic non-fusion fixators and other products) and so on.

National Medical Products Administration (NMPA) registered imported or domestic orthopaedic medical devices mostly use titanium alloy materials such as pure titanium, Ti-6Al-4V, Ti-6Al-7Nb and Ti-12Mo-6Zr-2Fe. Blanks such as plates, rods, and tubes are obtained by extrusion, rolling, and drawing. Subsequent processes such as machining are used to obtain products such as bone plates and screws, or femoral shanks, acetabular cups, intervertebral fusions, etc. are obtained by forging, 3D printing, etc. Products such as femoral shanks, acetabular cups, and intervertebral fusions are obtained.

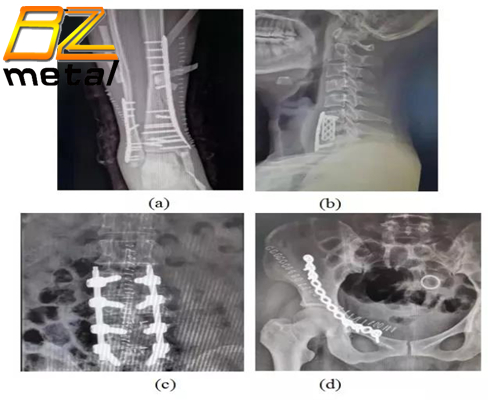

(a) Bone plate; (b) bone screw; (c) acetabular cup; (d) intervertebral fusion device products picture

(a) Titanium alloy plates and screws for fractures; (b) titanium cages for cervical vertebrae; (c) Titanium alloy

rods and screws are used for spine orthopedics; (d) Titanium alloy products are used for pelvic acetabular fractures

Progress in the Application of 3D Printing Titanium Orthopedic Implants

The 3D printing technology in the field of titanium orthopedic implants is mainly based on electron beam melting EBM (electron beam melting) and laser selective melting SLM (selective laser melting). Based on the computer-aided design model or the individual's clinical computed tomography (CT) and magnetic resonance imaging (magnetic resonance imaging) data, the titanium metal powder is layered and flattened, melted and solidified with an electron beam or laser beam as the energy source to obtain the final molded part.

The titanium orthopedic implant products currently on the market, such as acetabular cups, ankle fusions, artificial vertebrae, and intervertebral fusions, are mostly made of Ti-6Al-4V and pure Ti with EBM technology. The 3D printed products have a rough mesh structure, which has realized the perfect re-engraving of the human cortical bone and cancellous bone structure, and have been widely used clinically, especially in personalized customization. It has broad prospects.

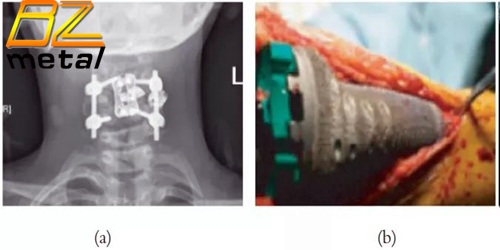

(a) 3D printing customized titanium alloy fusion device for placement in the cervical spine; (b) 3D printing titanium alloy tibial block

Replacement of bone tumor resection site.