All Kinds of Metal Material Forming Process--Forging

All Kinds of Metal Material Forming Process--Forging

Plastic Forming: Whic is using the plasticity of material, in the tool and mold of the external force under the processing of less cutting or even no cutting processing. There are many kinds of this producing method, including: forging, rolling, extrusion, drawing, stamping and so on.

I. Forging

1) Forging:

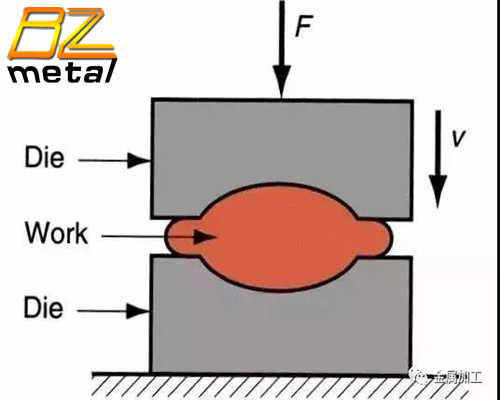

Forging is a processing method that uses forging machinery to apply pressure to the metal blank, and produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes.

According to forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.

① Free Forging: A processing in metal ingots or blocks, which are hammered to the desired shape and size with simple tools, usually by hammer forging or by hydraulic press.

② Die Forging: Formed with a die on a die hammer or a hot die forging press.

③ Roller Ring: Refers to the production of ring parts with different diameters by special equipment roller, also used to produce automobile wheel hub, train wheels and other wheel shaped parts.

④ Special Forging: Which including roll forging, cross wedge rolling, radial forging, liquid forging and other forging methods, these methods are more suitable for the production of some special shapes parts.

2) Processing:

Forging blank heating → roll forging preparation → die forging forming → edge cutting → punching → correction → intermediate inspection → forging heat treatment → cleaning → correction → inspection

3) Technical Features:

① Forgings have higher quality than castings, which can bear greater impact, plasticity, toughness and other aspects of mechanical properties are also higher than castings or even higher than rolled parts;

② Save raw materials, but also shorten processing working hours;

③ High production efficiency;

④ Free forging is suitable for small batch production with great flexibility.

4) Application:

Large rolling mill rolls, herringbone gear, steam turbine generator rotor, impeller, guard ring, huge hydraulic work cylinder and column, machine axle, car and tractor crankshaft, connecting rod, etc.