Excellence in Every Detail: The Journey of Custom CNC Titanium Parts Production

Time:2025-10-11

View:48

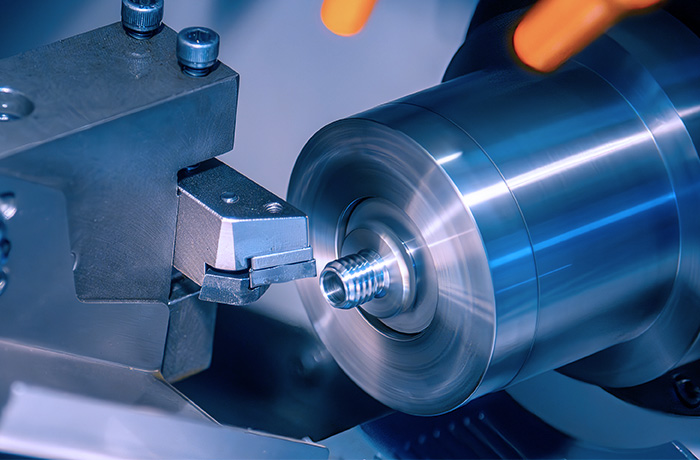

In our commitment to delivering high-quality custom CNC titanium parts, we understand that the production phase is critical. Our focus on using advanced processing technology, coupled with meticulous attention to detail, allows us to create exceptional custom titanium machining solutions tailored to meet the unique needs of our clients.

Advanced Processing Techniques for Precision

The foundation of our production capabilities lies in our use of advanced processing techniques. We leverage state-of-the-art technologies such as titanium CNC machining, laser cutting, and both cold and hot forming methods to ensure accuracy and surface smoothness in every component we produce.

By utilizing these innovative technologies, we can achieve precise dimensions and tight tolerances, which are essential for many applications, including aerospace, automotive, and medical industries. As a result, our custom titanium machined components deliver optimal performance while maintaining structural integrity.

Real-Time Process Monitoring

Another key aspect of our production process is the implementation of real-time monitoring systems. By continuously tracking critical process parameters—such as temperature, pressure, and speed—we can make timely adjustments that prevent deviations from quality standards. This proactive approach ensures that we maintain stable product quality throughout the manufacturing phase of our custom CNC titanium parts.

This level of oversight not only enhances our production efficiency but also reduces waste and rework. We believe that constant vigilance during production plays a vital role in reinforcing our reputation for reliability and precision in custom titanium machining.

Rigorous Process Management

To further guarantee the excellence of our custom CNC titanium parts, we strictly adhere to ISO quality management systems. This structured approach to process management allows us to refine our production operations, ensuring that every step complies with industry specifications for CNC titanium machining.

Our commitment to quality management extends to every member of our team, fostering a culture of accountability and continuous improvement. Through diligent training and clear communication of expectations, we empower our workforce to uphold our high standards, resulting in consistently superior products.

In conclusion, our dedication to ensuring excellence during production is reflected in every custom titanium machining project we undertake. BOZE CNC-Ti prides itself on implementing advanced processing techniques, real-time monitoring, and rigorous process management to deliver custom CNC titanium parts that exceed client expectations. We invite you to partner with us for your next project and experience the difference that our focus on quality can make in achieving your objectives.