Titanium wire is used in applications across Aerospace, Defense, Medical, Industrial. Used due to unique combination of high strength, light weight, corrosion resistance, biocompatibility, and higher temperature performance.

We can also melt special alloy ingot accoding to customers' requirement.

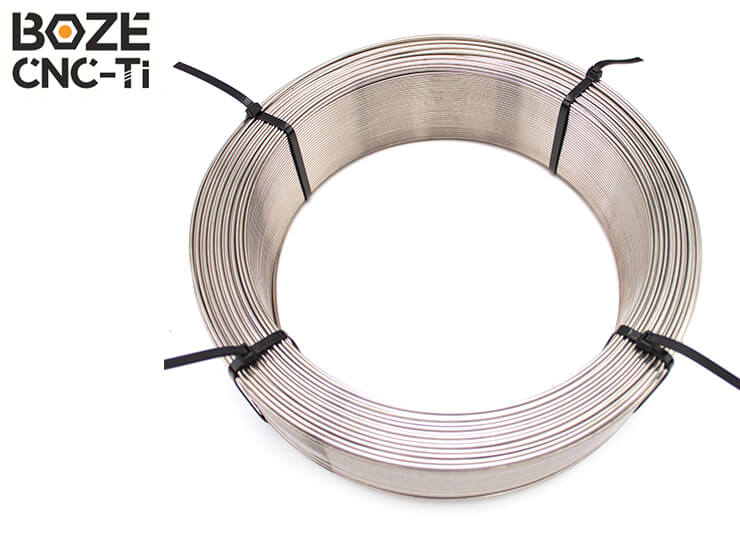

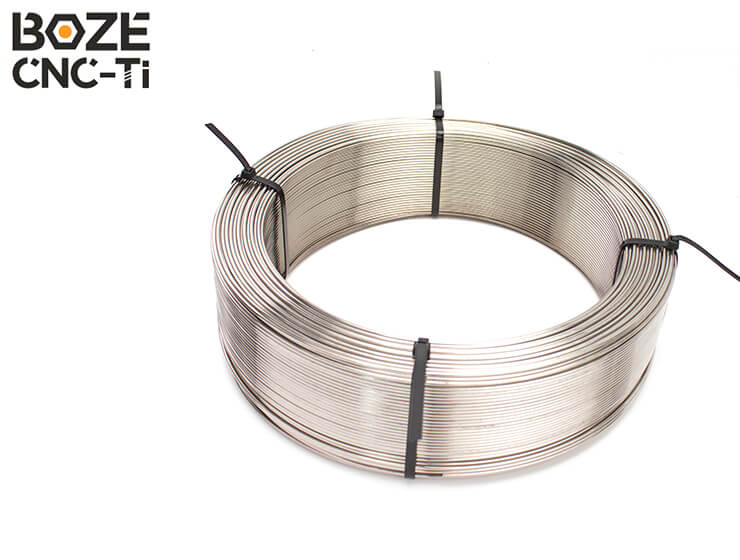

Product Name | Titanium Wire |

Material | Grade1 Grade2 Grade3 Grade4 Grade5(Ti-6Al-4V) Grade7(Ti-0.2pd) Grade9(Ti-3Al-2.5V) Grade11(Ti-0.2Pd ELI) Grade12(Ti-0.3Mo-0.8Ni) Grade23(Ti-6AL-4V ELI) |

Dimension(mm) | Dia(0.1-6.0)x coil |

Standard | ASTM B863/ASTM F67/ASTM F136 |

Processing | Forging/Rolling |

Surface | Polished/Pickling |

Condition | Annealing |

Application | Aerospace/Industrial/Oil & Gas/Medical/Defense |

1.What are the differences between titanium wire and titanium alloy wire?

Titanium wire is mainly made of pure titanium, with a density of 4.54g/cm³. It is corrosion-resistant but has relatively low strength. When titanium alloy wires are added with elements such as aluminum and vanadium, the strength of GR5/TC4 alloy is increased by more than 50%, and its heat resistance is better . For instance, GR5/TC4 titanium alloy wire is used in aviation fasteners, while pure titanium wire is mostly employed in spectacle frames.

The main difference between titanium wire and titanium alloy wire lies in their composition and properties . Titanium wire is made of pure titanium (such as TA1/TA2), which has good ductility but relatively low strength. Titanium alloy wire with added elements such as aluminum and vanadium (like TC4) can achieve a tensile strength of over 900MPa and has better high-temperature resistance.

2.In which fields is titanium wire most widely used?

The most widely used fields of titanium wire are aerospace, medical and health care, and chemical industry .

The reasons are as follows:

Aerospace : It is used to manufacture engine components, fuselage structural parts, etc., due to its light weight and high strength.

Medical and health : It is used for dental implants, fracture repair, etc., and has good biocompatibility.

Chemical industry : It is used to make filter screens, heat exchangers, etc., and has strong corrosion resistance.

3.What are the special properties of medical titanium wire?

Medical titanium wire possesses special properties such as high biocompatibility (cytotoxicity grade 0), low elastic modulus (2-30 gpa close to natural bone), high corrosion resistance (annual corrosion rate in 37℃ normal saline <0.0005mm/a), and high strength (GR5/TC4 tensile strength ≥895MPa) .

The special properties of medical titanium wire in clinical applications also include: non-magnetic (does not affect MRI examination), shape memory function (nickel-titanium alloy wire can restore the preset shape), antibacterial property (the surface titanium oxide layer inhibits bacterial adhesion).