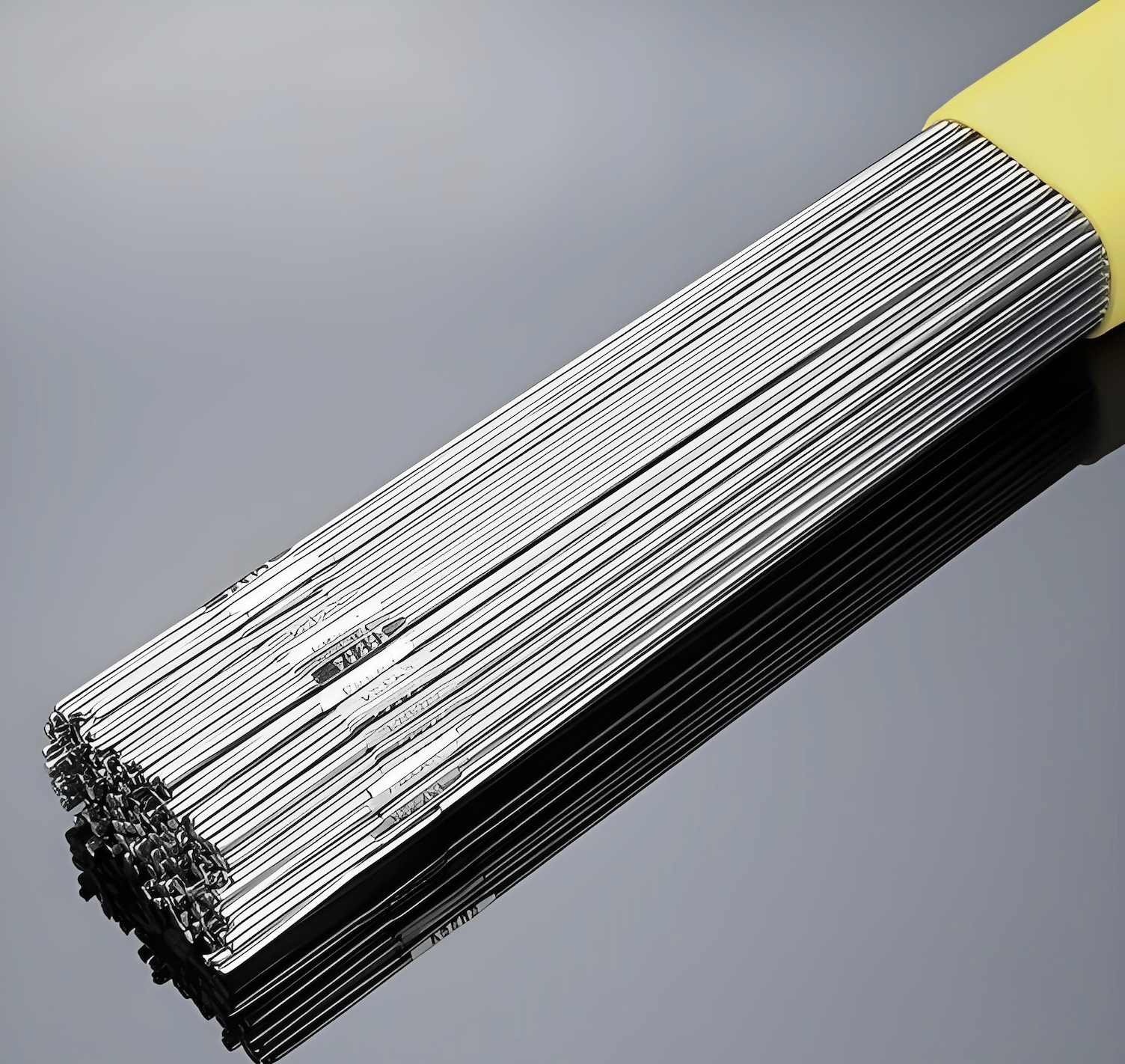

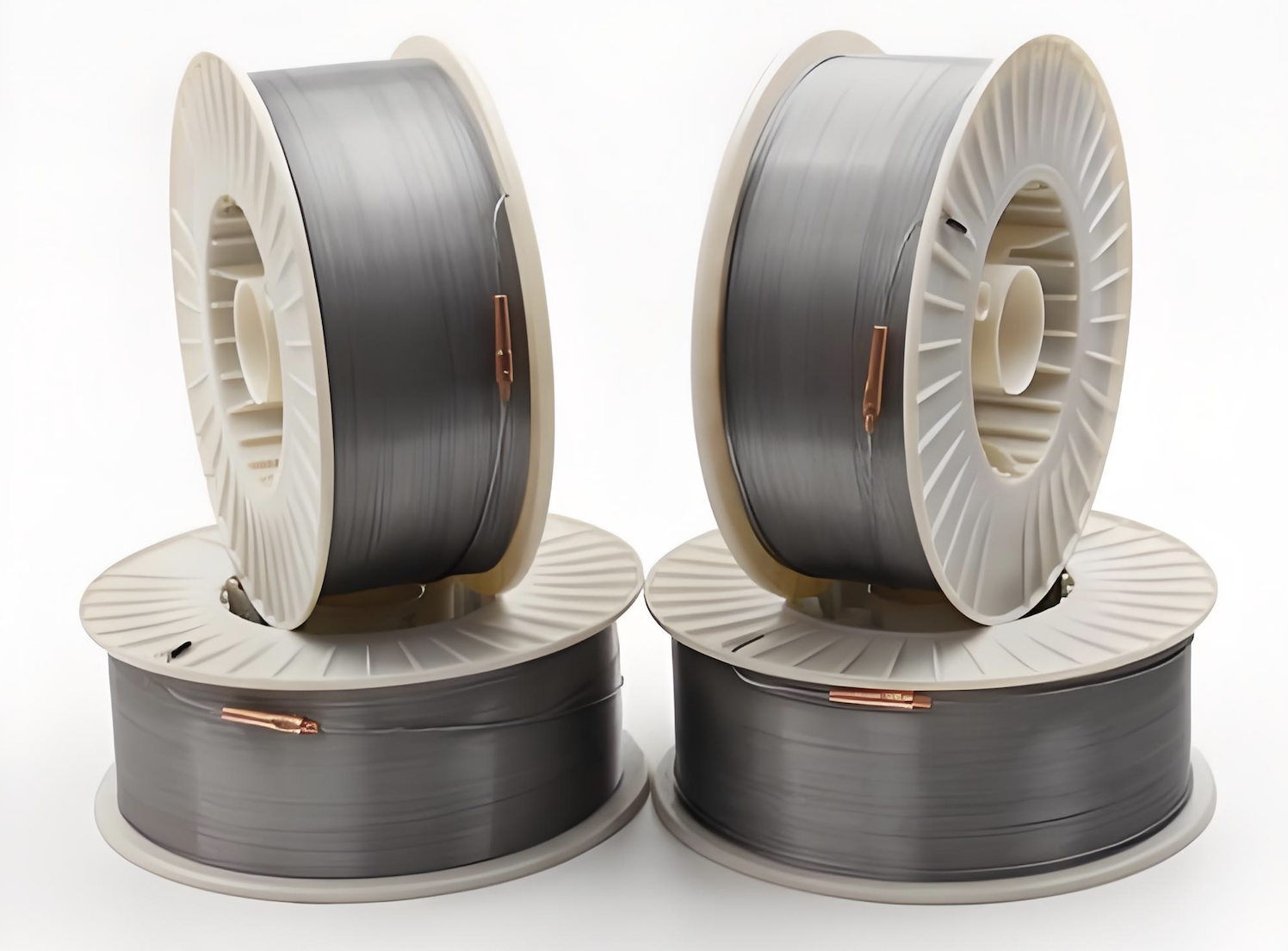

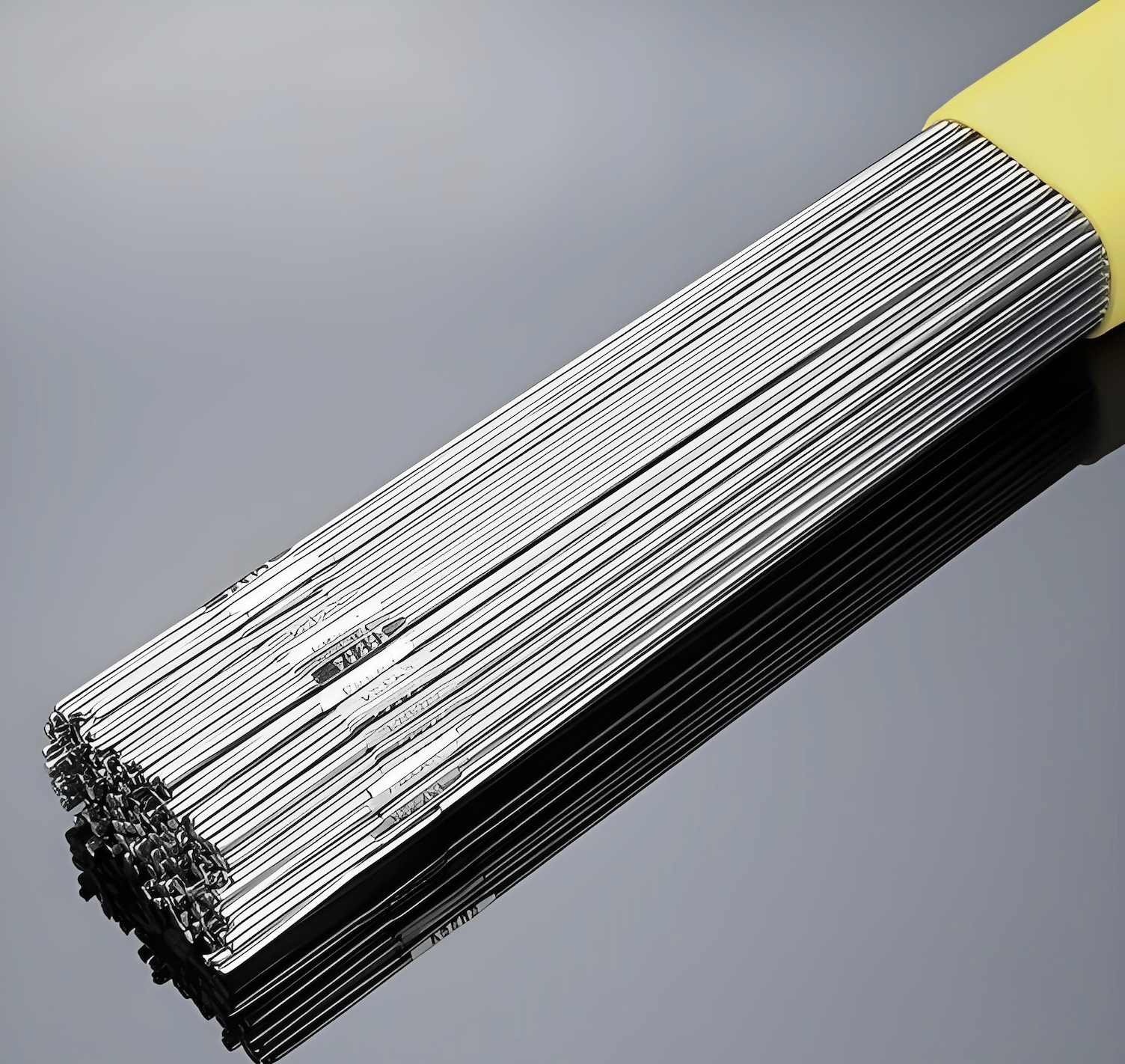

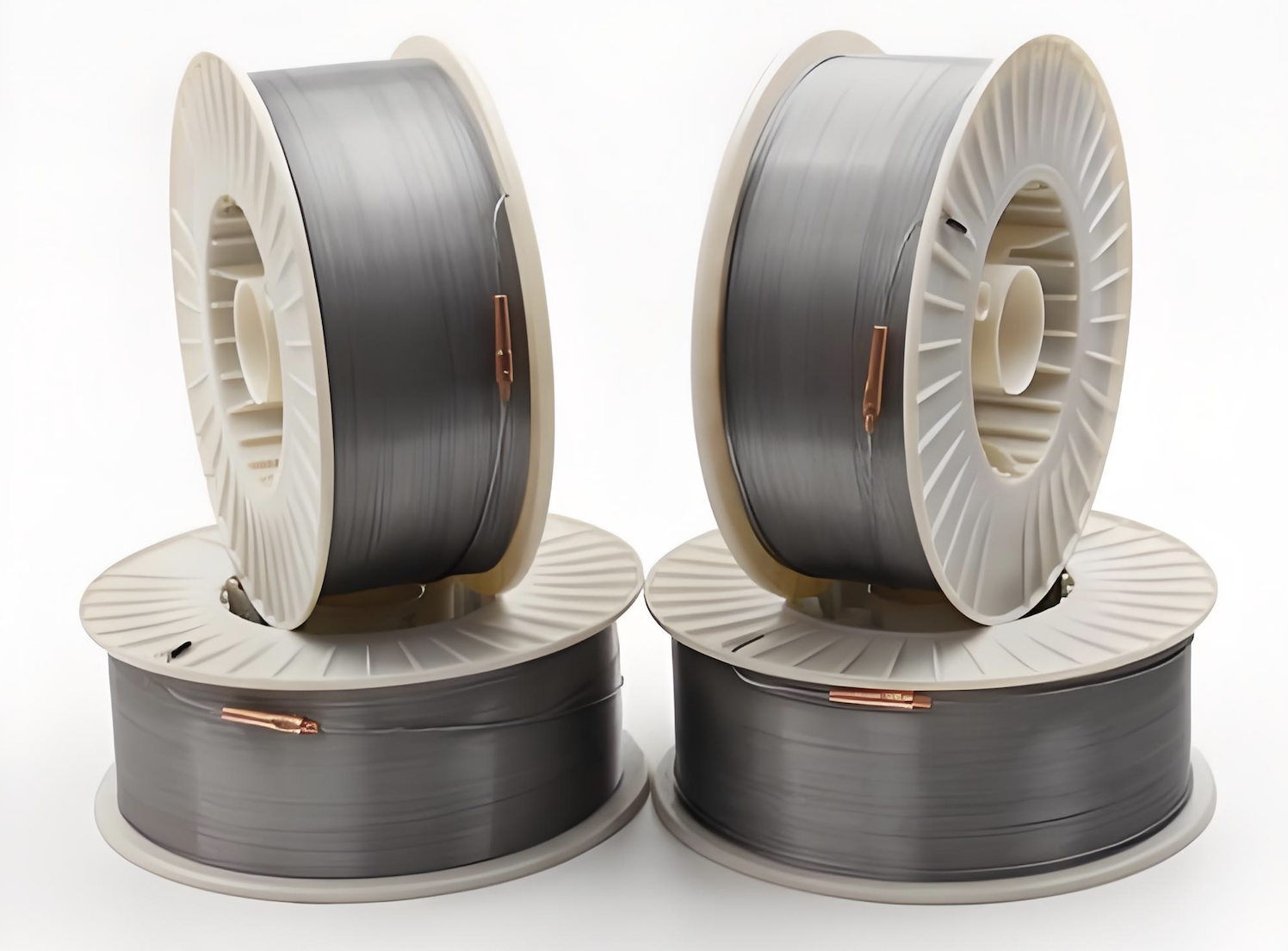

Titanium welding wire is a specialized material used for welding titanium and titanium alloys. The American standard models include ERTi-1, ERTi-2, ERTi-5, etc. The specifications range from φ0.8 to φ6.0 millimeters. It is available in two forms: coiled wire and straight wire, and complies with standards such as AWS A5.16/A5.16M.

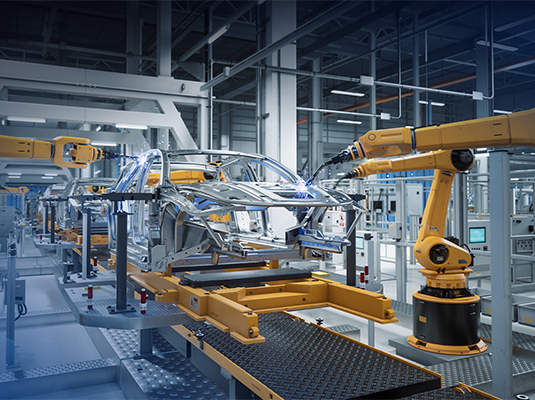

It is mainly applied in petrochemical equipment (such as reaction vessels, acid and alkali storage tanks), Marine anti-corrosion projects, medical equipment and aerospace fields.

When welding, clean gloves must be worn. The ambient wind speed should be controlled at ≤0.5m/s. A short arc and low heat input method should be adopted. The Angle between the nozzle and the workpiece should be maintained at 70 to 80 degrees, and the butt gap should be approximately 0.5 millimeters. The pipe welding adopts a single-sided welding and double-sided forming process. The bottom sealing welding and forming welding are completed in two steps. After welding, the gas supply needs to be delayed to below 250℃. The tensile strength of the product is 180MPa.

It is packaged in wooden cases or in the form of spool.

Product Name | Titanium Welding Wire |

Material | Grade1/Grade2 |

Dimension | Dia(0.8-6.0)x L(10-6000)mm |

Standard | AWS A5.16-13/ERTI-2/AMS 4951 |

Processing | Forging/Rolling |

Surface | Pickling |

Condition | Annealing |

Application | Aerospace/Industrial/Oil & Gas/Medical/Defense |