Prospects “Titanium” is Good, The Application Of Titanium Alloy in The Medical Field

Prospects “Titanium” is Good, The Application Of Titanium Alloy in The Medical Field

Titanium has the advantages of non-rust, antibacterial, non-magnetic, and non-deformation, and has become a widely used medical metal material in recent years. Due to the “biological” properties of titanium, it has good biocompatibility with human tissues and non-toxic side effects, so it has been widely used in the medical field.

According to research by American laboratories, the two types of titanium, 6Al-4V and 6Al-4V ELI, are most closely related to the medical field. 6Al-4V and 6Al-4V ELI are titanium alloys containing 6% aluminum and 4% vanadium. Because they have the strongest affinity with the human body, they are widely used in the medical field. In addition, in the United States Gr.5, Gr.23, these two types of titanium alloys are also used in different medical devices correspondingly according to different grades. At the same time, the two titanium alloys Ti-06AI and Ti-6AI-4V ELI are currently widely used in the dental field due to their strong structure and non-fragile properties. At present, some braces, dentures and other medical products have used these two titanium alloys.

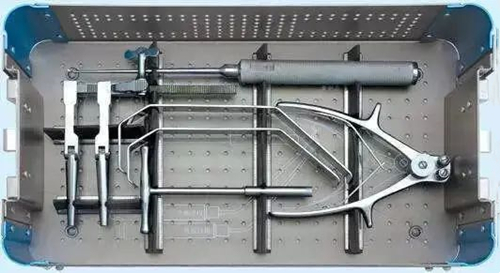

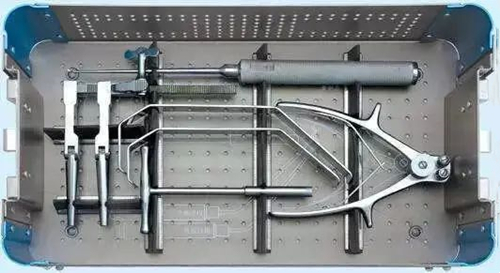

Application of Titanium in Medical Devices

Medical titanium alloy medical devices are the third generation of surgical instruments after carbon steel and stainless steel. In order to improve the rust resistance of stainless steel instruments, they often undergo surface treatments such as chrome plating and electropolishing. However, chromium is toxic, and the falling chromium layer will have a certain impact on the human body.

The benefits of medical titanium alloy as a medical device are:

1. The equipment is lightweight, which can reduce damage to blood vessels, muscles, and organs during surgery, and reduce fatigue of doctors. Medical titanium equipment is more suitable for fine microsurgery;

2. Good corrosion resistance and non-toxic, the equipment does not rust, the wound is not easy to be infected, and the wound heals quickly;

3. Medical titanium alloy has moderate elasticity and is suitable for pliers, tweezers, micro-scalpels and other instruments;

4. When operating under shadowless lights, medical titanium has weak reflective properties, which is more suitable than stainless steel.

Medical titanium medical equipment mainly includes: scalpels, surgical forceps, surgical tweezers, chest expanders, suture needles, sutures, etc. Medical titanium wire is used as a surgical suture. Compared with other materials (such as stainless steel wire), it has the advantages of small tissue response and good torsional resistance. After suture, the surgical wound is not easy to become inflamed, and the bone suture site is not easy to shift. Medical titanium wire (TA1 or TA2 wire) with a diameter of 0.5~0.8mm is generally used for sutures. In addition, the soft elasticity that titanium-nickel alloy wire can produce can promote rapid wound healing.

In addition, medical titanium alloy is also an important material for auxiliary rehabilitation equipment, such as wheelchairs, crutches, splints, medical equipment, etc.

Application of titanium in pharmaceutical industry

In pharmaceutical production, since the production of medicines cannot be separated from acids, alkalis, and salts, pharmaceutical equipment can easily be corroded and damaged. The use of steel equipment will not only fail to solve the problem of serious equipment corrosion, but will also cause a lot of human, material and financial losses, affecting normal production. The use of titanium equipment solves this problem well.

In the production of several major commonly used medicines, equipment made of titanium has good corrosion resistance and has obtained considerable economic benefits.

1. Vitamin B1 production

In my country, the hydrogen chloride conversion method is used to produce vitamin B1. The finished product is dried by cyclones and separated by cyclones twice. Its medium is thiamine hydrochloride, with a pH value of 2.5 and a temperature of 110℃, which is very corrosive. The original drying device was made of stainless steel, and the inner wall was corroded and perforated after more than a year of use, which seriously contaminated the medicine.

After adopting titanium spiral feeders, cyclones, vortices, hoppers, discharge pipes, and titanium lining of exhaust tanks, the production pass rate of vitamin B1 has been increased from up to 95% to 100%, and the equipment has not been corroded for more than 7 years, and the titanium cost can be recovered within 3 months.

2. Vitamin C production

Vitamin C is based on sorbitol as raw material, fermented into sorbitol by black vinegar bacteria, and then fermented with Pseudomonasillus to obtain a low concentration of colonic acid. After concentration, it is converted by hydrogen chloride to obtain the finished product.

Titanium is very resistant to corrosion in high-temperature colonic acid. In the production process of this product, a titanium tubular heat exchanger, a titanium DHC-500 butterfly sedimentation automatic slag discharge centrifuge, and a TC4 cast impeller are used. No corrosion has been found after many years of use.

3. Antibacterial production

The main raw material for the chemical synthesis of chloramphenicol (an antibiotics) is methyl dichloroacetate, which contains about 2% chlorinated alkenes and trichloroethylene. Among them, if steel equipment is used in the refining process, it is prone to serious corrosion. It has been intact since it was switched to titanium equipment.

4. Narcotic drug production

Procaine hydrochloride used under local anesthesia is produced from p-nitrotoluene as raw material. It is highly corrosive in the entire production process of oxidation to p-nitrobenzoic acid, washing with acetic acid, and recovery of mother liquor. Therefore, the production equipment adopts titanium steel composite plate inner tube, titanium bubbling tube, glacial acetic acid circulating condenser and vapor-liquid separator, thereby solving the corrosion problem.

5. Production of insect repellents and other medicines

Roundworm repellent (tetraimidazole) is a high-efficiency intestinal nematode insect repellent. Stainless steel equipment was originally used in the production of this product. Due to corrosion, the product was contaminated. Titanium was used as the feed pipe and the pump inlet pipe. The corrosion problem was successfully solved.

Niclophenol is a special veterinary medicine for the treatment of flukes in cattle and sheep liver tablets. It is produced from sulfuric acid, nitric acid, glacial acetic acid and chlorine-containing solutions. The agitator made of titanium is used to sell the chemical tank, and it has been operating normally so far. In addition, activated carbon decolorization is generally used in pharmaceutical production, and after the stainless steel suction filter is changed to a titanium suction filter, it is still intact after 9 years of use.

In the production of brominated amino acids abroad, titanium reactors are used in the bromination, separation, salting, extraction, and steaming processes. Titanium equipment is also necessary for the preparation of malarial drugs from quinoline derivatives, anti-schistosomiasis drugs that are exposed to chloride ions, contraceptives, and rheumatism drugs in my country. Others such as penicillin esterification kettle, saccharification tank, chloramphenicol thin film evaporator, analgin reactor, Mitul filter, dimethyl sulfate cooler, liquid medicine filter, etc., all have the feasibility and necessity of using titanium material for manufacturing.

Titanium for medical use is rapidly approaching us. With the rapid development of society and economy and the improvement of people's living standards, the demand for biomedical materials and their products will continue to rise, which will further promote the application of titanium.