Development Of Low-Cost Titanium Alloy Materials

Development Of Low-Cost Titanium Alloy Materials

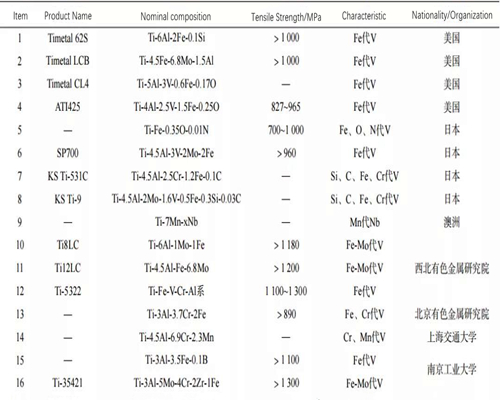

In order to reduce the production cost of titanium alloy materials, countries around the world have carried out research on new titanium alloy materials. The main way is to replace expensive elements such as V, Mo, Zr, Nb, and Ta with cheap intermediate alloys such as Fe, Si, Al, and Sn. Based on the above ideas, the main low-cost titanium alloys currently developed at home and abroad are shown in Table 1.

1. Timetable 62S Alloy

Timetable 62S (Ti-6Al-2Fe-0.1Si) alloy is a new type of low-cost titanium alloy designed and developed by Timetable Company in the United States for non-aerospace purposes. It belongs to the α+β alloy. The original intention of the alloy design is to replace Ti-6Al-4V alloy. Fe element is used instead of V element in Ti-6Al-4V alloy. The addition of an appropriate amount of Si can refine the structure. The alloy performance is not inferior to that of Ti-6Al-4V, the cost is reduced by 15%~20%, and it has excellent hot and cold processability. The alloy is mainly used in high-strength, damage-resistant titanium alloy sheet metal structural parts in the civil field, and has replaced Ti-6Al-4V alloy in the production of valve seats.

2. Timetable LCB Alloy

Timetable LCB (Ti-4.5Fe-6.8Mo-1.5Al) was developed by Timetable Company in the United States and is a high-strength β alloy. The alloy was originally designed to replace Ti.-10-2-3 (Ti-10V-2Fe-3Al), add Fe element in the form of Fe-Mo intermediate alloy to replace V element. Timetable LCB alloy has high strength and good formability. It can be cold-processed or temperature-processed like steel, and its performance is the same as Ti.-10-2- 3 is equivalent, and the cost is 78% of Ti-6Al-4V. Mo in this alloy is a Β-stable element, which can form compounds of Fe and Mo, and has high tensile strength after aging hardening. It has been used in automobile parts, springs and suspension springs in Japan and the United States.

3. ATI425 Alloy ATI425 Alloy

(Ti-4Al-2.5V-1.5Fe-0.25O) is a β-type low-cost titanium alloy developed by ATI Wah Chang in the United States. It replaces part of the V element with Fe element, which reduces costs, has good mechanical properties and corrosion resistance, tensile strength can reach 827~965MPa, yield strength can reach 758~896 MPa, elongation can reach 6%~16%, and the elastic resistance is comparable to Ti6Al4V, which meets the requirements of current military armor standards for material properties, and has been used in armor plates and armor plates in the field of weapons. Military vehicle parts.

4. Ti-Fe-O-N series Alloys

Ti-Fe-O-N series alloys are Β-type alloys developed by Nippon Steel Corporation and Toho Titanium Corporation. These alloys use Fe, O, and N elements instead of the V elements in Ti-6Al-4V alloys, of which 0.5%~1.5% Fe, 0.2%~0.5%O, and 0.05%~0.1%N are used. The strength of this alloy system can reach 700~1 000MPa at room temperature, but its high temperature performance is poor. The representative of this alloy series is Ti-1% Fe-0.35%O-0.01%N. The tensile strength of this alloy is about 800MPa, and it is mainly used for alloys designed for purposes other than aviation.

5. SP700 Alloy

SP700 (Ti-4.5 Al-3V-2Mo-2Fe) is a superplastic titanium alloy material developed in Japan. It can achieve superplastic forming and diffusion connection at 775℃. The superplastic forming temperature is lower than that of Ti-6Al-4V alloy, and the tensile strength and fatigue strength are better than that of Ti-6Al-4V alloy. It can be used to manufacture thin sheet-shaped aerospace structural parts. Because it avoids the defects of titanium's high deformation resistance and poor plasticity at room temperature, the deformation processing cost of titanium material is greatly reduced. Japan applies this alloy to Honda NSX motorcycle connecting rods, and the United States RMI Titanium Company prepares this titanium alloy into aircraft structural parts and rotating parts.

6. Ti8LC and Ti12LC Alloys

Through alloy design and performance testing, Northwest Institute of Non-Ferrous Metals has developed a low-cost titanium alloy of near-α type Ti8LC and Ti12LC. It is a TiAl-Mo-Fe alloy. Cheap Fe-Mo intermediate alloys are added to the alloy to replace the V and Zr in the Ti-6Al-4V alloy. At the same time, pure titanium waste (such as titanium shavings) is added during the smelting process to reduce the amount of sponge titanium. On the basis of guaranteed performance, the cost of raw materials can be reduced by more than 10%, and the preparation cost of small bars can be reduced by about 30%. After solution aging and heat treatment, the two alloys have good strength, plasticity and fatigue strength. The tensile strength at room temperature can reach more than 1100MPa, and the strength and plasticity are higher than the Ti-6Al-4V alloy in GB/T 2965. Ti12LC alloy has higher strength and plasticity matching, with a strength of 1200MPa and a plasticity of 20%, which is better than Timetable 62S and Timetable LCB alloys. Ti8LC and Ti12LC can be used to prepare automobile intake and exhaust valves, bicycle torsion bars, etc., of which Ti12LC can also be used to prepare tail nozzles for aerospace solid rocket engines.

7. Ti-5322 Alloy

Ti-5322 alloy is a Ti-Fe-V-Cr-Al α+β two-phase titanium alloy developed by Northwest Institute of Non-Ferrous Metals for non-aviation applications. The alloy fully considers the application of cheap Fe elements and recycled titanium materials. 2% Fe is added instead of the expensive alloying element V. The cost is lower than that of Ti-6Al-4V alloy. After heat treatment, the alloy has good strength and toughness matching, and its room temperature strength reaches 1100~1300 MPa, and the elongation is 7%~14%. At present, this alloy has been used in the development of tank armor, and its elasticity resistance is better than that of TC4 alloy.

8. Ti-35421 Alloy

Ti-35421 alloy is a new type of high-strength titanium alloy for offshore engineering developed by Nanjing University of Technology in response to the needs of high-strength, impact-resistant, corrosion-resistant and weldability of titanium alloys for offshore engineering. The tensile strength is 1 313 MPa, the yield strength is 1 240 MPa, the elongation is 8.62%, the cross-section shrinkage is 17.58%, and the fracture toughness KIC is 75.8MPa·m1/2. The stress corrosion sensitivity in 3.5% NaCl solution is small, and it has good corrosion resistance. This alloy completes the domestic low-cost titanium alloy material system for marine use with a strength level of 1,000MPa, which is of great significance for the selection of equipment in the design and construction process.